- Home

- Virtual booth

Environmentally friendly and always walkable

Our virtual booth

The perfect interplay of drive technology, thread technology, gear technology and BLDC technology

The prerequisite for the development of our drive solutions lies in our core competencies is the drive technology, thread technology, gearing technology and BLDC technology

The machine-technical heart of our production are computer-controlled machining centers, CNC lathes, thread rolling machines and gear machines of the latest generation. We manufacture the individual parts of our customer-specific drive solutions ourselves on the basis of our own CAD designs. Ketterer's know-how is in the design and manufacture of threaded spindles, gear wheels, bevel and worm gears, linear drives and geared motors, as well as of BLDC motors.

We are Furtwanger - and where we live, that's where we produce!

Innovationsgeist, Präzision und Umweltverbundenheit sind seit der Gründung durch Benedikt KetThe spirit of innovation, precision and a love for the environment have become our very own company tradition since it was founded by Benedikt Ketterer in 1832. Where everything began with the early Black Forest precision mechanics, we are still developing and producing today as a family-run global player. And that with excellent quality management and committed employees.

-

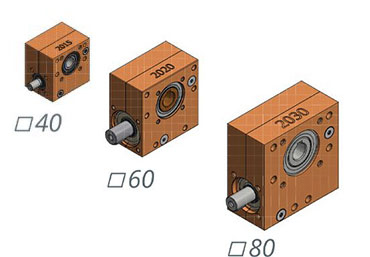

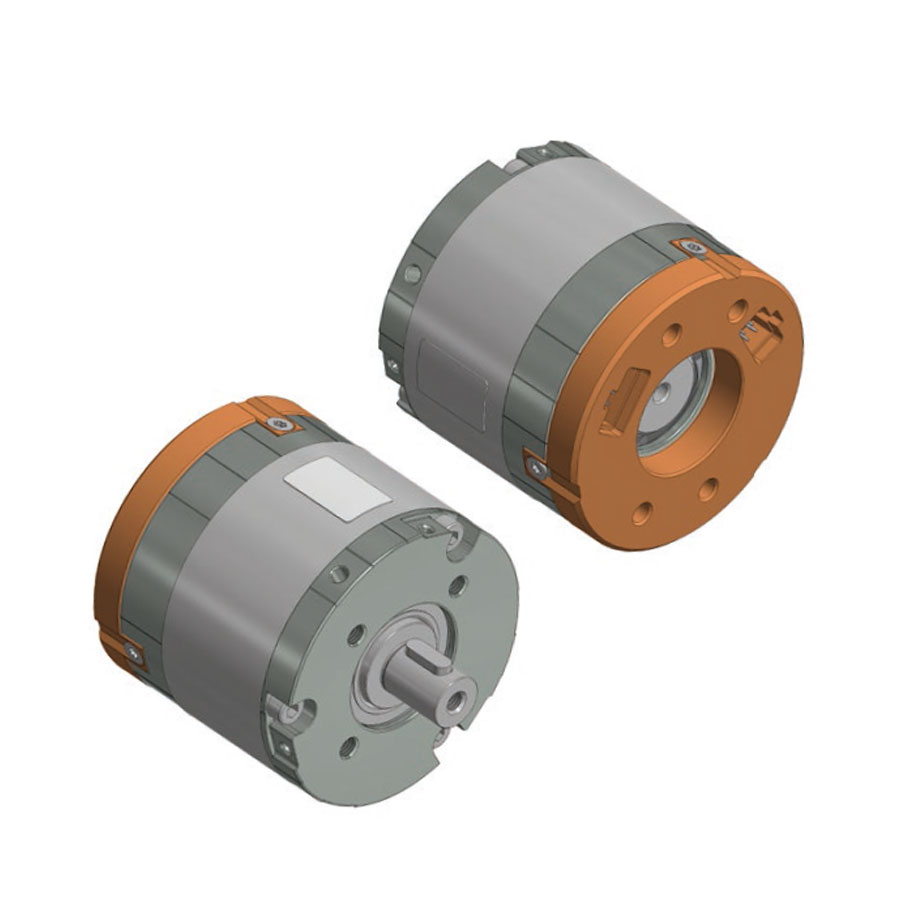

Worm gearbox family Ket-Motion

Universally usable and maintenance-free worm gear in three differenz sizes.

The housing is encapsulated to prevent the escape of grease and the ingress of dust. The worm gear pair is left-handed. The direction of rotation on the shaft is arbitrary.

Highlights:

- 3 sizes with axis distances 15, 20 or 30 mm

- Up to 9 different ratios

- With one drive pin or through going axis

- High quality metal gear components guarantee long service life

- Ketterer produces the components itself at the manufacturing site in Furtwangen

- Housing anodized aluminum, orange as standard, other colors possible to suit customer requirements

- Gear units with higher transmission ratios are statically self-locking

- Maintenance-free grease lubrication

More information about worm gearbox family Ket-Motion (brochure)

Worm gear Ket-Motion 2015 with feather key groove

Special features

- Axis distance 15 mm

- 7 reduction ratios from 1:1 to 47:1

More information about worm gear Ket-Motion 2015 (data sheet)

Data sheet Ket-Motion 2015Worm gear Ket-Motion 2020

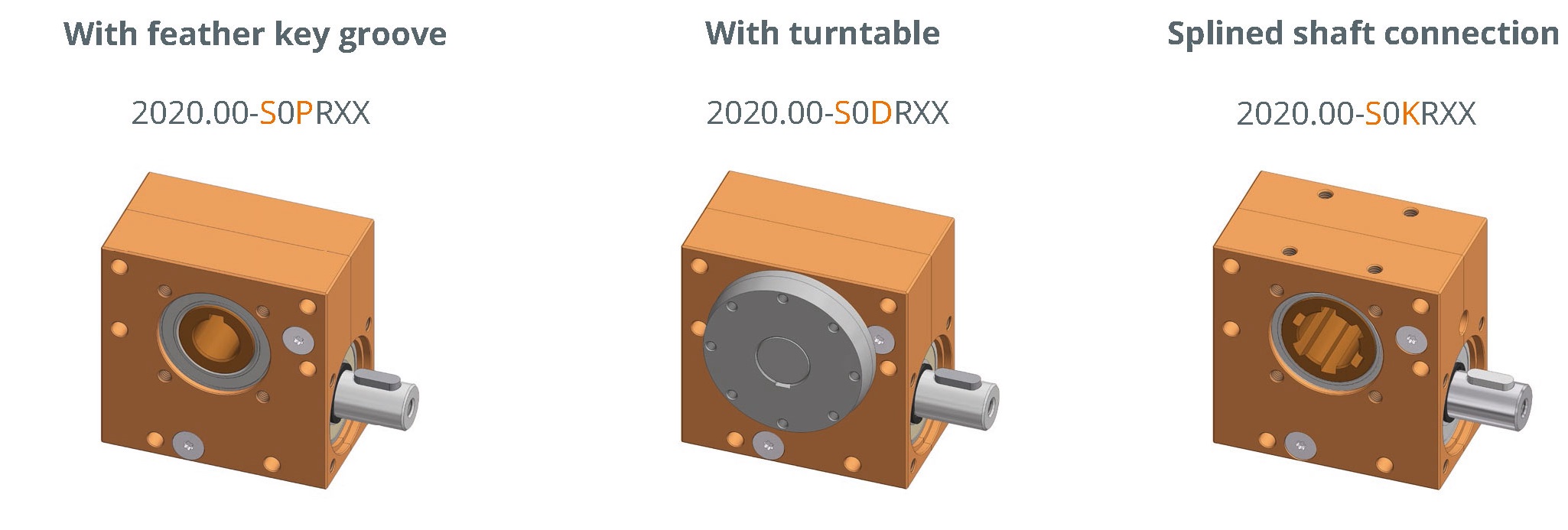

The worm gear pair is left-handed. The direction of rotation on the shaft is arbitrary.

Special features

- Axis distance 20 mm

- 9 reduction ratios from 1:1 to 65:1

- Different variants: with feather key groove, turntable or splined shaft connection

More information about worm gear Ket-Motion 2020

Data sheet Ket-Motion 2020Worm gear Ket-Motion 2030

Special features

- Axis distance 30 mm

- 9 reduction ratios from 1:1 to 64:1

More information about worm gear Ket-Motion 2030

Data sheet Ket-Motion 2020Extensive range of accessories

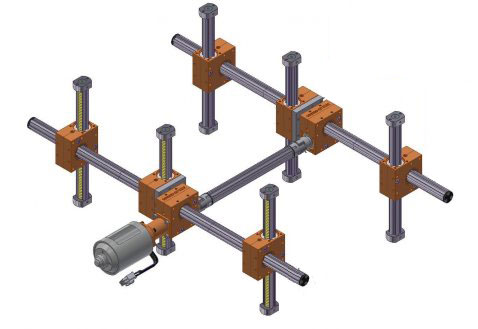

Via connecting flange, Coupling shafts and electronic control from our extensive range of accessories can be synchronized. The gearboxes can easily be lined up so that, for example, two drive trains perform the same movement.

Ketterer also has the fitting motors for this purpose:

-

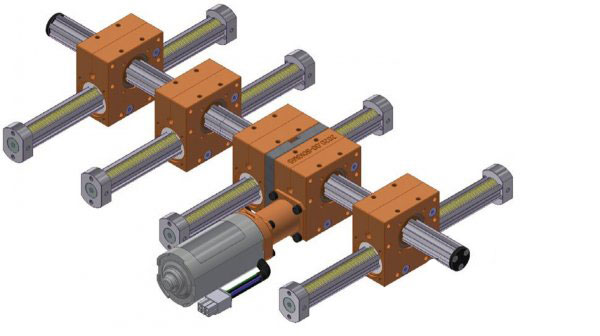

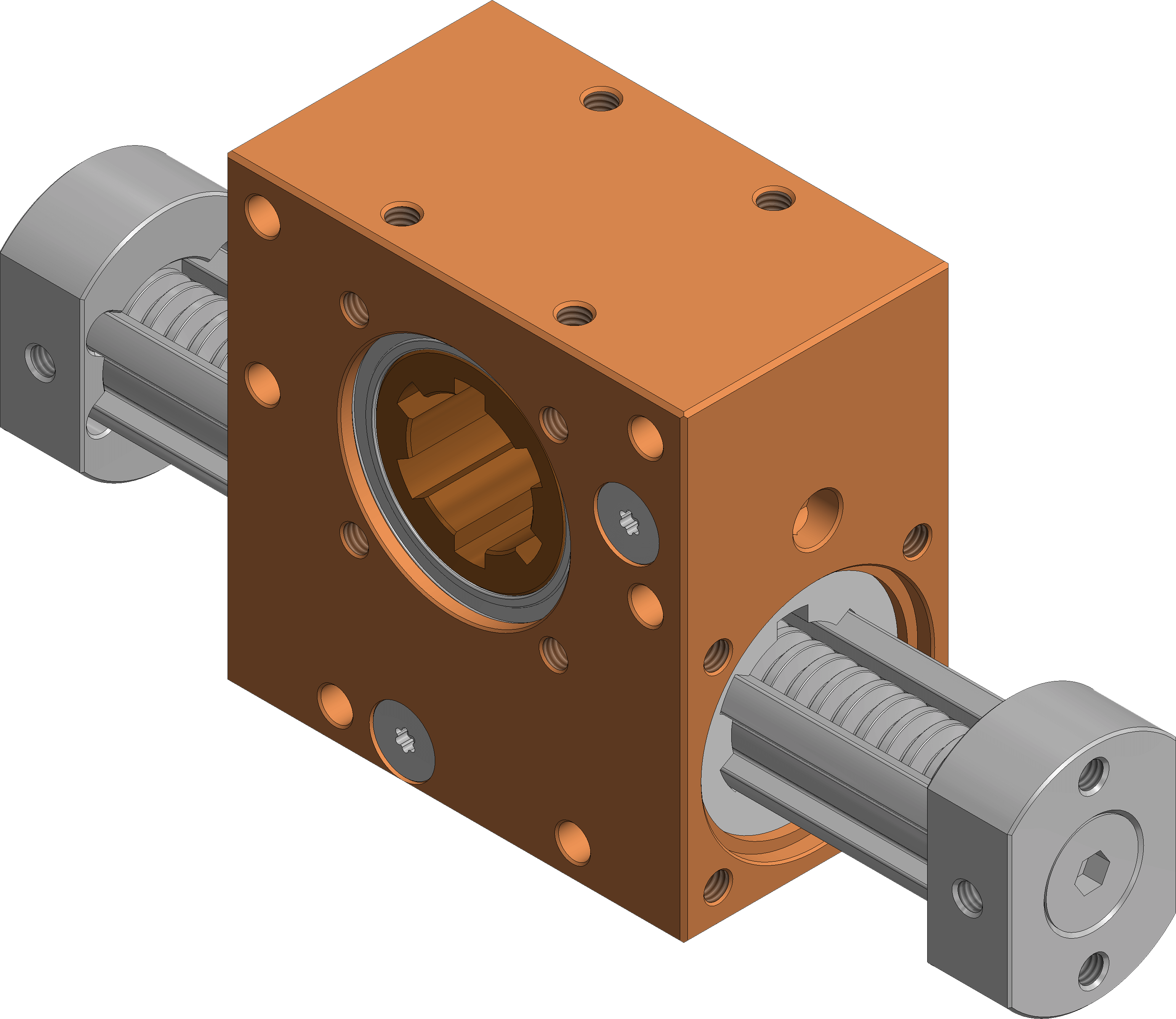

Rack and pinion gear Ket-Motion 2020 Z

The function of the universally applicable linear gear units is to convert rotating movements into axial ones.

They are used wherever vertical or horizontal transport, lifting, pushing or steering is required. As an electromechanical variant, these special gear- boxes often replace hydraulics and pneumatics. Thanks to a rack that can be freely scaled in length, the stroke can be freely selected to suit the application.

Special features

- Axis distance 20 mm

- Housing anodized aluminum, orange as standard, other colors possible to suit customer requirements

- Feed per revolution 87 mm

- Backlash < 0.5 mm

- Max. speed 100 mm/s

- Application temperature -20°C to +60°C

- Lubrication and maintenance free

- Stroke HXXXX: freely selectable

More information about rack and pinion gear Ket-Motion 2020 Z

Data sheet Ket-Motion Z

More worm gears by Ketterer (brochure) -

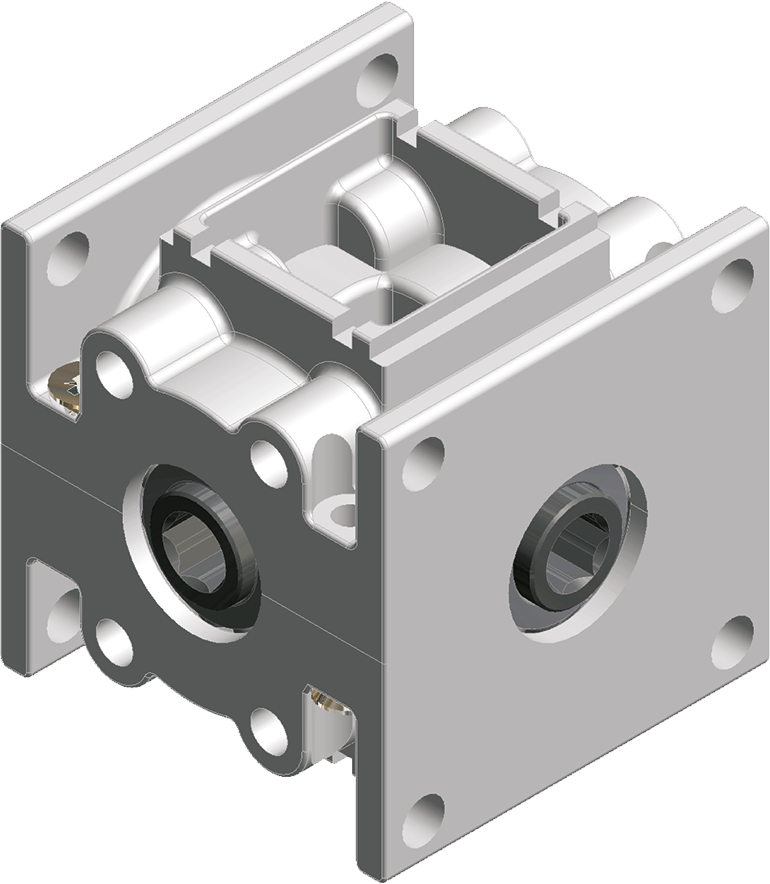

Bevel gear 3869/ 3870

Bevel gearboxes for the deflection of a rotary movement. Ideal for use as a transfer gearbox or ancillary gearbox for electric motors, e.g. for blinds or actuators in special mechanical engineering.

Special bevel gear toothing ensures smooth running of the gearbox. The gearbox can be combined with any spindle. The modular structure of the gearbox allows special customer requests to be met even with small numbers of items.

Special features

- Maintenance-free

- Hardened, bearing seated steel gear cogs

- Housing made of zinc die-casting

- Ratio 1:1

- Up to four inputs are possible

- On require hex 6 mm, blind hole or through hole possible

- Lifetime 20,000 load changes: with 10 Nm, 110 U/min, with the duty cycle 30 s ON 240 s OFF and at + 25 °C Housing made of zinc die-casting

More information about bevel gear 3869/3870

Data sheet worm gear 3869/3870

More worm gears by Ketterer (brochure) -

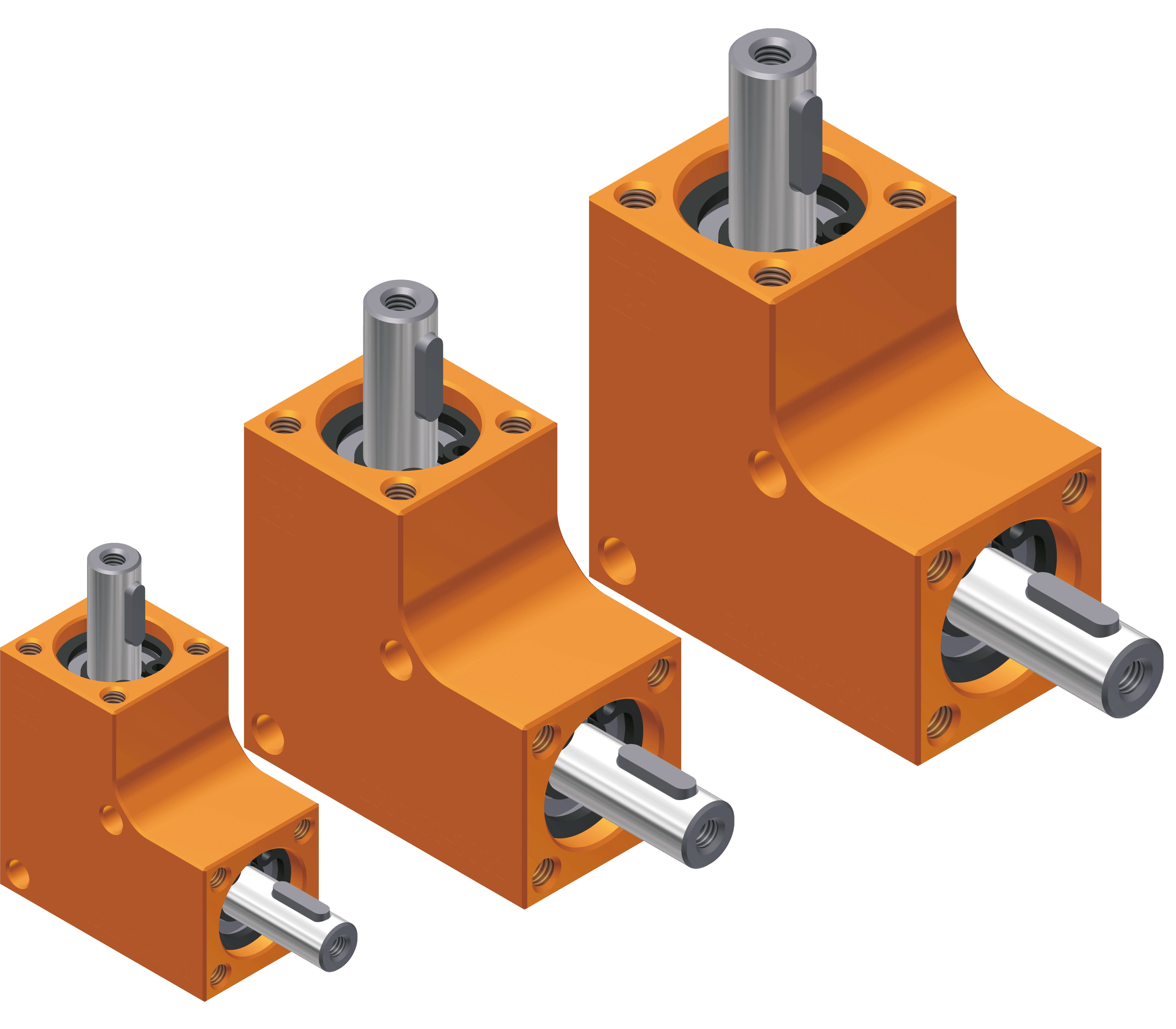

Angular gear Ket-Bee 200X

Ket-Bee is a bevel gearbox family consisting of 7 sizes for versatile use as an angular gearbox.

The angular gearbox is characterised by a compact design with maximum torque, sturdiness and smooth power transmission. The uncomplicated mounting of the angular gear is made possible by a simple screw fixing.

Special features

- Maintenance-free

- Steel bevel wheels, case-hardened

- Aluminium housing, anodized (orange or silver)

- Silent running

- Ratio 1:1

- Permitted operating temp. -20 °C to +60 °C

- Backlash at drive shaft 3° ± 1°

- Duty cycle 20 % at 5 min (1 min ON, 4 min OFF)

- Lifetime of 1000 hours with:

- full load and

- nput speed of 500 rpm and

- duty cycle 20% with 5 min

More information about angular gear Ket-Bee 200X

Data sheet angular gear Ket-Bee 200X

More bevel gears by Ketterer (brochure) -

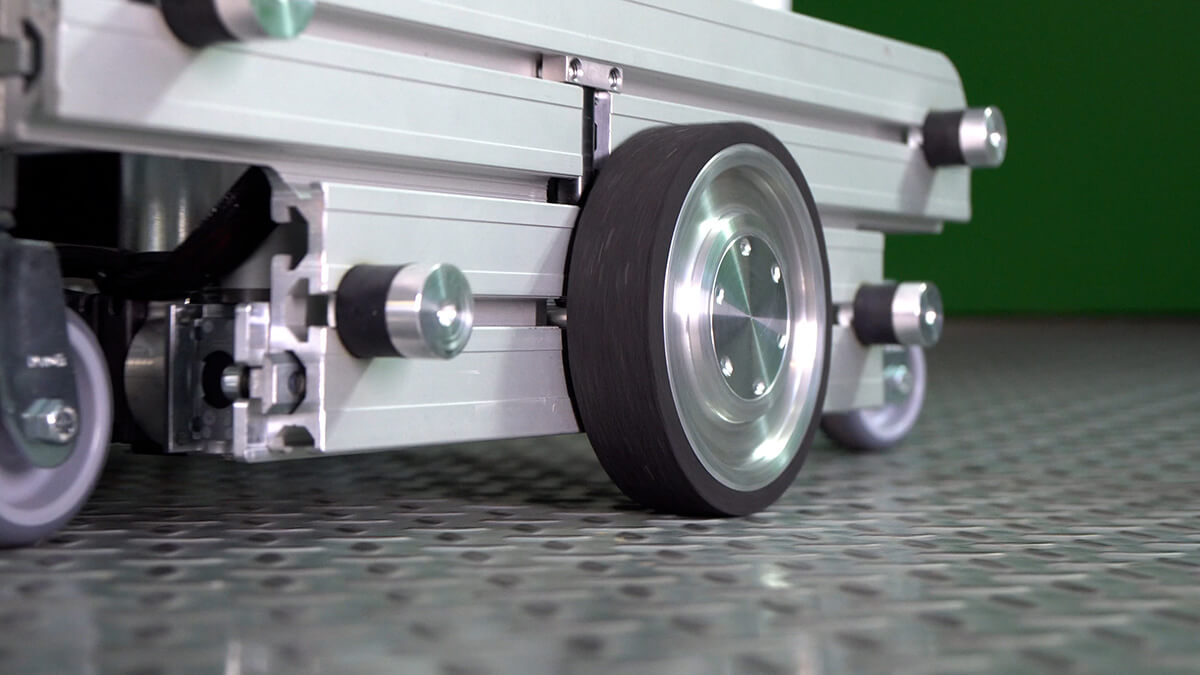

Ket-Rob - Drive platform for AGV/AGC

Ketterer has developed a modular drive platform “Ket-Rob”. “Ket-Rob” forms the basis for customer-specific automated guided vehicles (AGVs) or automated guided carts (AGCs) and can be quickly and flexibly adapted to individual requirements in practice.

Ketterer’s “Ket-Rob” can save many development steps and resources when developing an innovative AGV or AGC.

More information about Ket-Rob

Data sheet Ket-Rob

Wheel hub motors by Ketterer (brochure) -

ON REQUEST

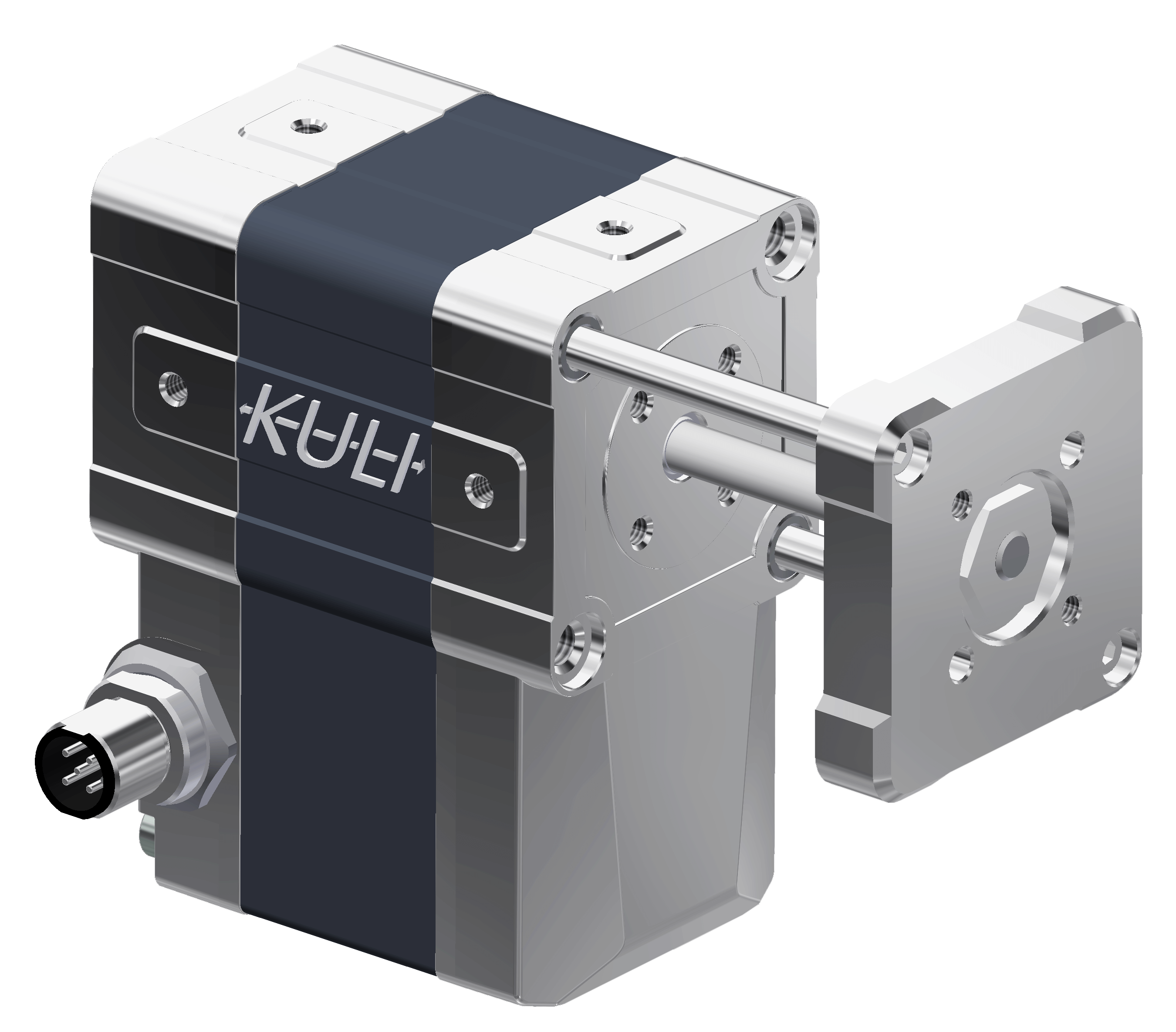

KuLi - electrical short stroke actuator

Compact and fast electrically operated linear drive. The drive is particularly suitable for use in automation and conveying technology. The parameterization takes place via a connect box (sold separately). The control electronics are integrated.

Special features

- Compact design

We achieve a stroke of 40 mm with a housing length of just 67 mm - Powerful and dynamic

Thrust/tensile forces up to 300 N, speed up to 445 mm/s - Easy parameterization

User friendly software and connect-box - Integrated control

Configuration and teach-in of the system without expert knowledge - Maintenance-free

- Compact design

-

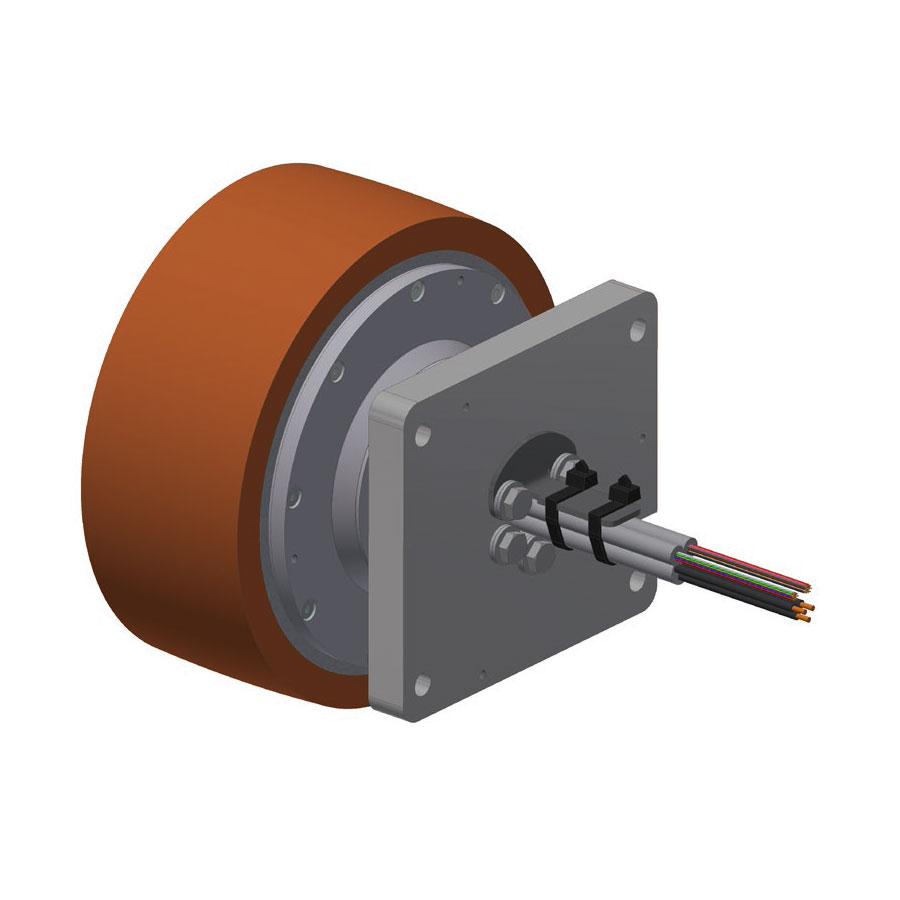

Wheel hub motors i-Wheel 3213 for use in Automated Guided Vehicles (AGV)

The Ketterer i-Wheel 3213 wheel hub drives have been specially developed for use in Automated Guided Vehicles (AGV).

They are designed as direct drives that are completely integrated in the wheel and therefore need neither an additional gearbox nor an extra motor.

The i-Wheel 3213 series consists of three high-performance wheel hub drives, which can reach torques up to 34 Nm and speeds up to 27 km/h.

Special features:

- Neither a gearbox nor an extra motor is needed

- Ultra-compact for tight installation spaces

- High power density in the smallest installation space

- Much longer service life compared to conventional drive technology with a gear stage

- No gear – no wear

- Easy to replace the wheel coating

- Very good running properties with minimal noice level

More information about Wheel hub motors family i-Wheel 3213

Data sheet i-Wheel 3213.00-1XXX

Data sheet i-Wheel 3213.00-2XXX

Data sheet i-Wheel 3213.00-3XXX

Wheel hub motors by Ketterer (brochure) -

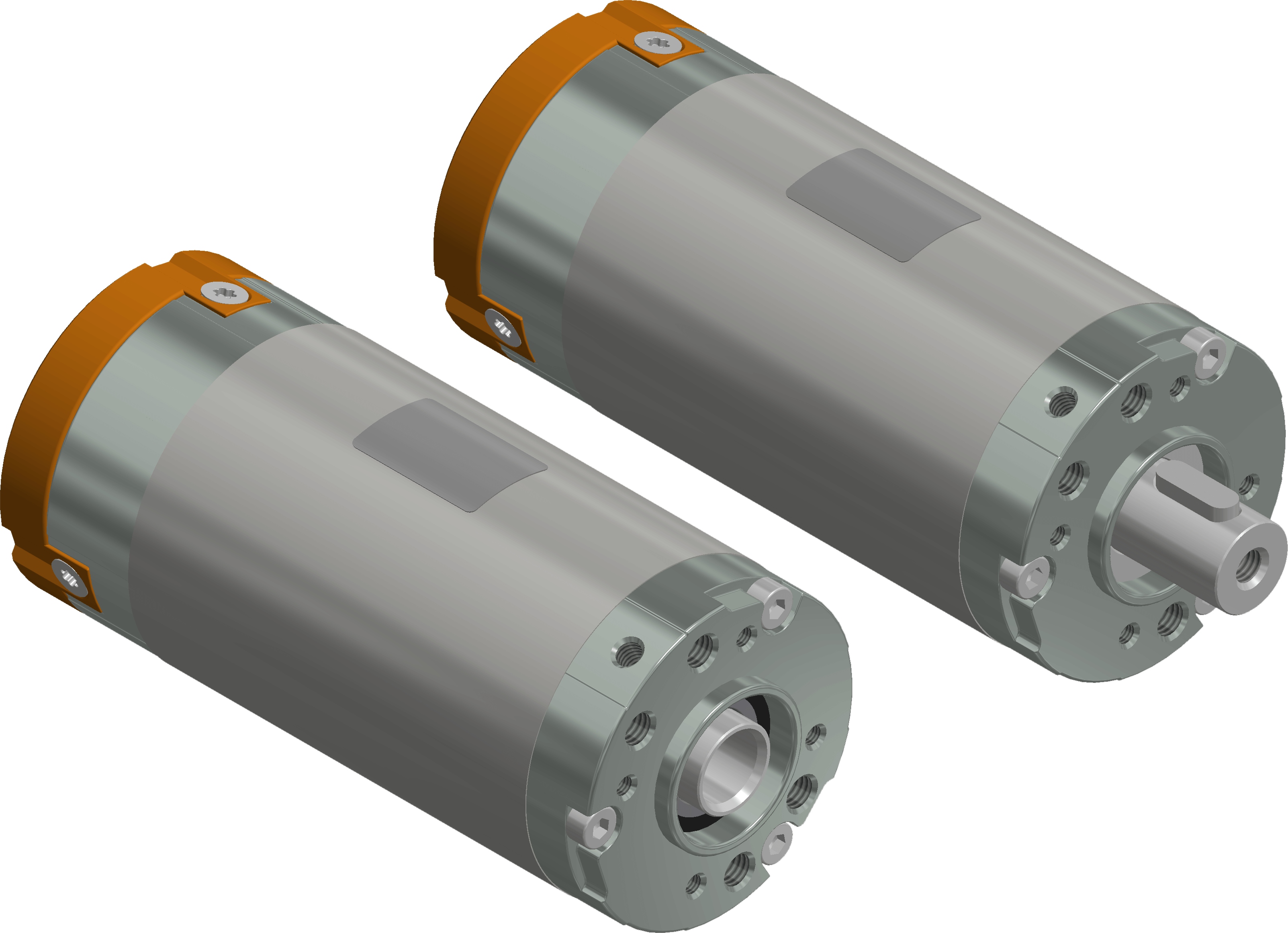

BLDC motors 3200 and 3206

Ketterer t-Rex BLDC motors are high-performance, compact and reliable. The drives are available in 2 sizes (3200: Ø44mm and 3206: Ø65mm) and in 2 lengths

Compared to currently available BLDC motors of the corresponding size, the t-Rex family features triple torque density in the smallest installation space.

Our inrunner motors have 14 powerful neodymium magnets, which gives them a higher torque as well as making them suitable as direct drives. The torque spectrum of the t-Rex family starts at 0.2 Nm and reaches a value of up to 8 Nm. Speed range up to 5000 1/min.

We are happy to accommodate client-specific requirements

Special Features

- No gearboxes - no wear, resulting in a much longer service life

- No maintenance - no operating costs, thus increased machine uptime

- Reduced noise due to elimination of the power transmission mechanism

- Battery operation also possible

- Combinable with commercially available controllers

- Customer-specific motor layout possible

- Solid shaft with key or hollow shaft on customer request

t-Rex 3206 I-65-86-L36 S2 (long version, focus torque)

Brief description

- Idle speed up to 1390 rpm

- Stall torque up to 9 Nm

- Rated torque 1.9 Nm

- Rated speed up to 1185 rpm

Data sheet t-Rex 3206 I-65-86-L36 S2

t-Rex 3206 I-65-51-L36 S2 (short version, focus rotational speed)

Brief description

- Idle speed up to 6054 rpm

- Stall torque up to 1.9 Nm

- Rated torque 0.6 Nm

- Rated speed up to 4812 rpm

Data sheet t-Rex 3206 I-65-51-L36 S2

t-Rex 3200 I-44-89-L41 S2 (long version, focus torque)

Brief description

- Idle speed up to 1653 rpm

- Stall torque up to 2.9 Nm

- Rated torque 0.5 Nm

- Rated speed up to 1347 rpm

Data sheet t-Rex 3200 I-44-89-L41 S2

t-Rex 3200 I-44-47-L41 S2 (short version, focus rotational speed)

Brief description

- Idle speed up to 5483 rpm

- Idle speed up to 5483 rpm

- Rated torque 0.2 Nm

- Rated speed up to 4437 rpm

Data sheet t-Rex 3200 I-44-47-L41 S2

t-Rex 3200 I-44-89-L12 S2 (long version, focus rotational speed)

Brief description

- Idle speed up to 4053 rpm

- Stall torque up to 2 Nm

- Rated torque 0.3 Nm

- Rated speed up to 3767 rpm

Data sheet t-Rex 3200 I-44-89-L12 S2

Torque-Motors t-Rex (brochure)

BLDC-Technology by Ketterer (brochure) -

Next Generation AGV Platform

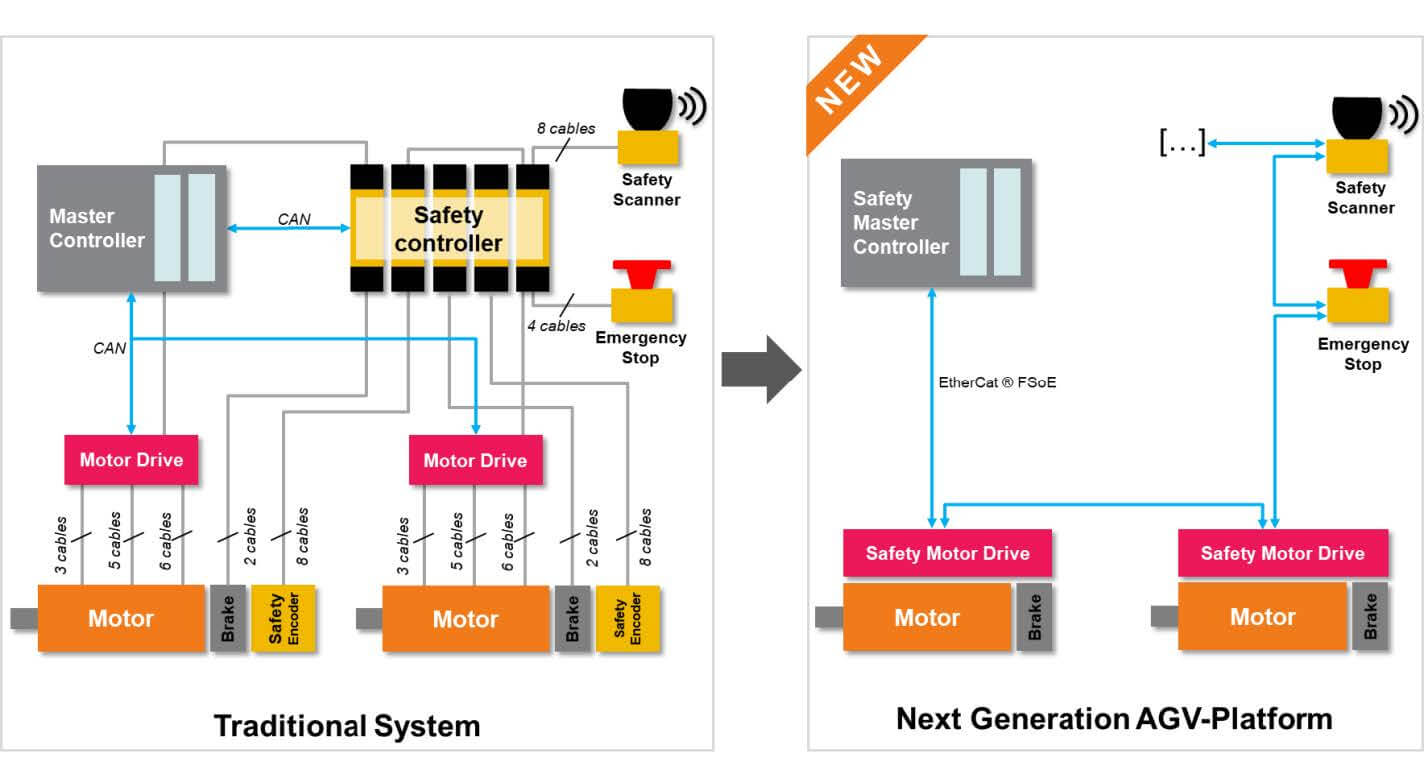

In cooperation with the companies SICK, Synapticon, Kontron and Brinkmann, Ketterer has developed a future-oriented integrated system for AGV system architecture.

The system architecture of an AGV presently on the market usually consists of a multitude of components from different manufacturers. Such system architecture is very time-consuming and the huge quantity of necessary components and their cabling require considerable space.

The „Next Generation AGV-Platform„ reduces components and cabling and offers further significant advantages.

The safety motor controller is built directly on the ultra-compact Ketterer wheel hub drive i-Wheel 3213. Both safe and unsafe signals of the Safety Master Controller are transmitted via EtherCat® FSoE to all components on the network. This system architecture provides many advantages for AGV manufacturers, including:

- Ketterer wheel hub drive i-Wheel 3213 without gearbox

- No additional safety encoder necessary on the drive

- Reduces the cabling, installation space und the number of parts by more than 50%

- Simple cabling of parts

- Data transmission of secure and unsecure parts via protocol

- Expandable as desired

- More battery space, resulting in longer runtime and higher availability

- Lower system costs

- Scalable and future-proof with EtherCat® FSoE

- SIL2 / PL-d

- Safety Master Controller for simultaneous safety, navigation and movement control

More information about Wheel hub motors family i-Wheel 3213

Data sheet i-Wheel 3213.00-1XXX

Data sheet i-Wheel 3213.00-2XXX

Data sheet i-Wheel 3213.00-3XXX

AGV-Platform Next Generation (brochure)

Wheel hub motors by Ketterer (brochure)