BLDC motors from Ketterer – Powerful, precisely controllable drives for automated guided vehicles (AGVs) and automated guided carts (AGCs)

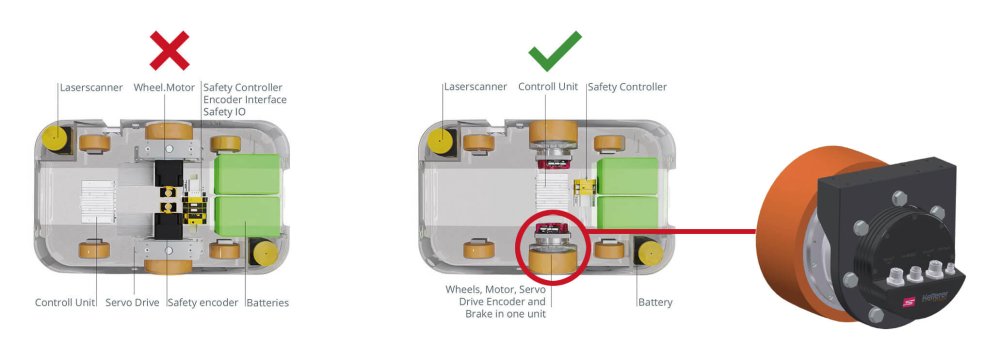

Increased performance with reduced system costs

| Fewer components | More space | |

| Fewer cables | More efficiency | |

| Less complexity | More performance |

Visit our new virtual booth!

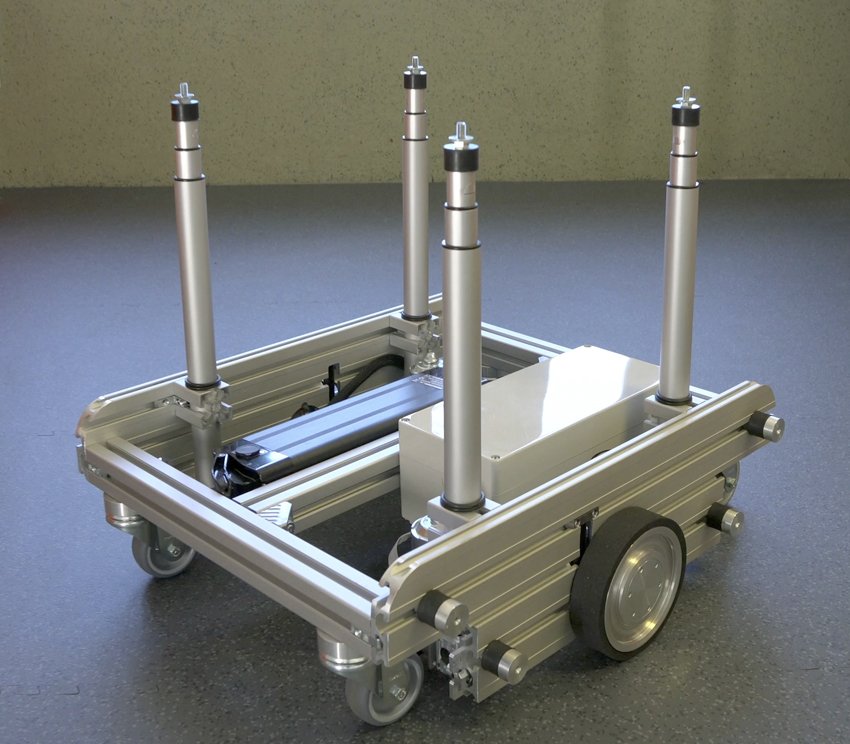

The new modular drive platform for your AGV and AGC system – “Ket-Rob” from Ketterer

The abundance of possibilities for efficient application with an autonomous AGV / AGC system can be difficult to manage, even for experts. This raises the question of a solution with which new ideas and strategies for the use of an autonomous AGV / AGC system can be implemented quickly and at low cost.

This is why Ketterer developed the modular “Ket-Rob” drive platform, which forms the basis for customer-specific AGV / AGC systems and can be adapted quickly and flexibly to individual requirements in practice. Ketterer’s “Ket-Rob” helps to save both resources and many development steps along the way to an innovative AGV / AGC system.

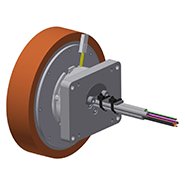

Thanks to wheel hub drives, Ket-Rob works without additional gearboxes

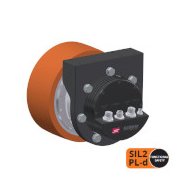

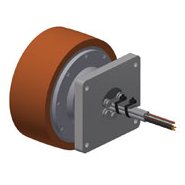

The centerpiece of the Ket-Rob is the i-Wheel 3213 wheel hub drive. This makes it the only modular drive platform currently available on the market for AGV and AGV solutions without an additional gearbox. This brings many advantages: low wear, smooth running and maximum design freedom.

It is equipped with a height-adjustable carrier platform. The steering wheels can rotate freely around the steering axis. The system can turn on the spot with the drive wheels rotating in opposite directions.