Application Area Industrial Drives

Dynamic drive solutions for the requirements in conveying technology, logistics and automation of tomorrow

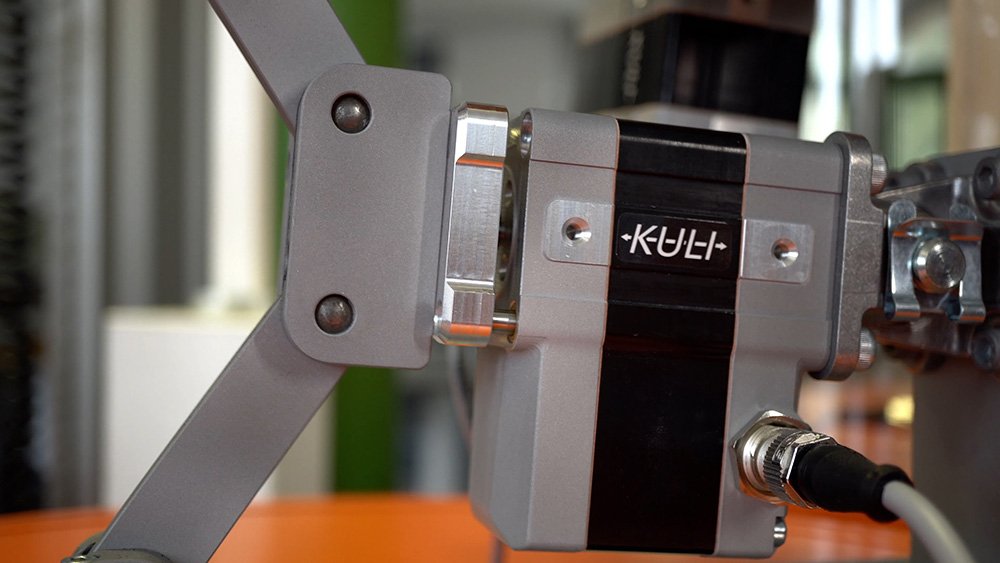

Equipped for Industry 4.0 with Ketterer's BLDC technology

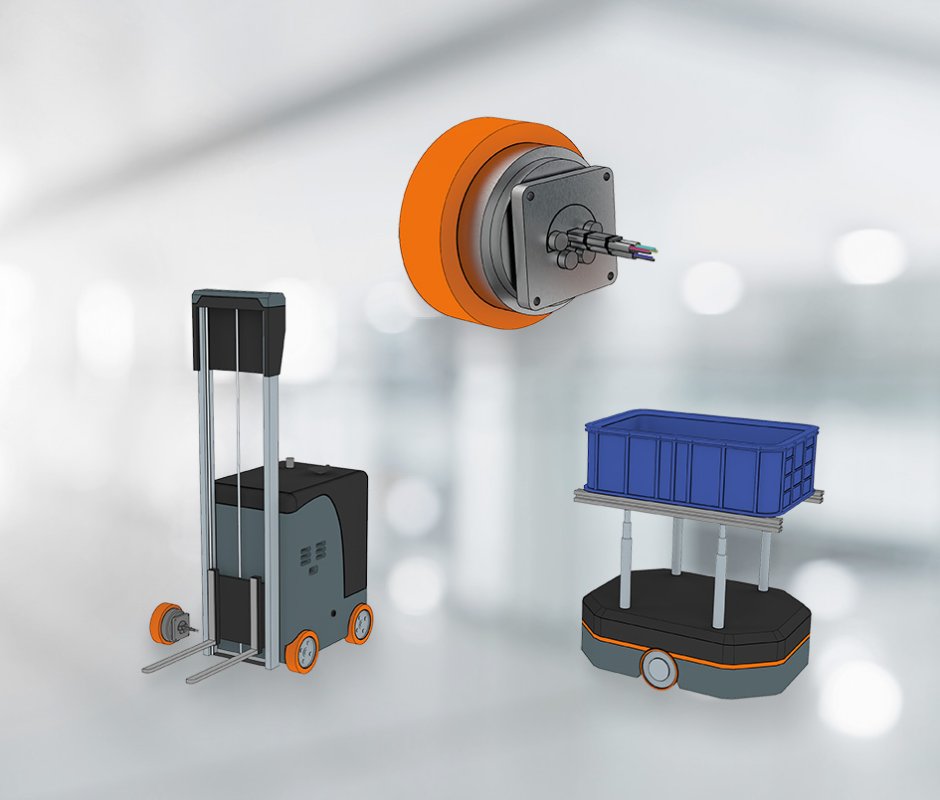

In the age of Industry 4.0, Automated Guided Vehicles (AGV) and Automated Guided Carts (AGC) have become indispensable part of modern logistics. The possible applications are as diverse as the tasks that an AGV and AGC can take on. In hospitals, they are among the most important transport solutions due to their efficiency and safety. AGVs and AGCs have also revolutionized the intralogistics sector - they optimize material flows and thus the entire value chain.