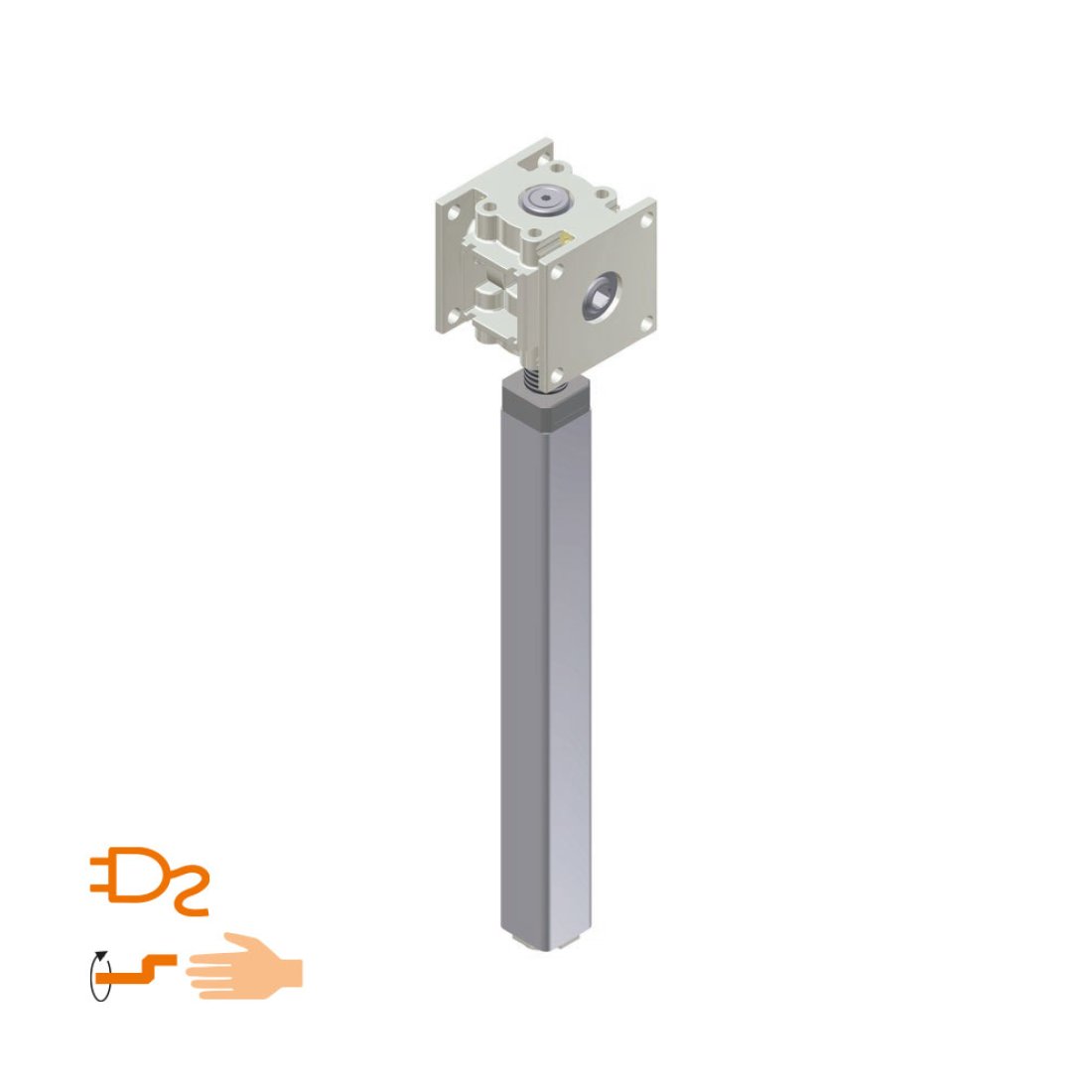

Bevel gear with spindle unit 3042 | 3043

Description

Universally applicable lifting unit with bevel gear head for linear drive solutions. Possible applications are height adjustable tables, various adjustment functions for furniture items as well as all manner of linear adjustment in residential, mobile home or industrial fields. A simple screw fastening enable a simple system structure and an uncomplicated assembly.

Special features

- Maintenance-free

- Housing made of die-cast zinc

- Hardened steel bevel wheels with robust, reinforced toothing

- Ratio 1:1

- Drive torque on gear head for application with several spindle units: max. 10 Nm

- Perfect suitable for electromotive drives

- More flexibility through variable number of bevel gears for deflection of movement

- Available in various construction lengths and spindle pitches

Variant key

3042: variants with right rotating spindles

3043: variants with left rotating spindles

Technical notes

- The lifting units must be protected against lateral forces by a separate guide system.

- Attention: The spindle systems with a spindle pitch > 3mm may not be self-locking. Check the self-locking effect in the application.

- The lifting unit is only pressure loadable.

- If several lifting units are being used simultaneously in the application, note the max. drive torque on gear head of 10 Nm!

- Incorrect dimensioning of the guide system can damage the lifting unit: Please note the design and safety instructions for spindle drives. You will find them at: https://www.ketterer.de/en/downloads/instructions

| Model | 3042 | 3043 |

| Ratio | 1:1 | 1:1 |

| Input | hex 7 mm | hex 7 mm |

| Number of bevel wheels | max. 3 | max. 3 |

| Type of spindle | SG12x12P4 RH clockwise | SG12x12P4 RH counter-clockwise |

| Travel path | 12 mm/rotation | 12 mm/rotation |

| Traverse speed* | 24 mm/s | 24 mm/s |

| Max. stroke | retracted length -105 mm | retracted length -105mm |

| Max. lifting force | 1200 N | 1200 N |

| Required drive torque | 2.6 Nm | 2.6 Nm |

| Max. drive torque gear ahead for several spindle units** | 10 Nm | 10 Nm |

* In combination with motor drives 3143.00-200X and LogicData control box Compact-3

** See technical notes

3D data (in STEP format) is saved as a zip file on your computer. After unpacking the files, you can open and view the data with an STP viewer (e.g. the free Autodesk Viewer). To download our 3D data, you have to log into your customer account. If you do not yet have a customer account, you can register now.